Testing (Rev 2)

Photos and videos documenting the testing of the the Rev 2 version of the field ventilator.Testing Flow (see photos and videos below)

To test flow from the Rev 2 Units, we connected standard 15mm CPAP hose with 22mm elastic cuffs to two patient ports on each of three manifolds. The other end we connected to 15LPM “Liter Meters.” Rev 2 units allows us to operate each manifold on a different respiratory rhythm (i.e. CPAP, BIPAP, or X:Y Inhale:Exhale). By opening and closing the individual ball valves, we were able to adjust individual flows per port to simulate different tidal volume demands. . Flow to entire manifolds can be increased and decreased by adjusting the exhaust valve at the end of the manifold opposite the air supply end. This proved very useful in modulating fluctuation in port flows. This will need to be validated on a test lung and clinically.

It is also possible to reduce manifold room air flows to the entire system by partially opening the air pump bypass line in order to increase FiO2 when 100% oxygen is blended with room air. We ran the bypass line at approximately 20 LPM throughout testing. The bypass line is located upstream of the air pump check valve to prevent 100% oxygen from backflowing the pump and/or being vented from the air bypass line (which wastes oxygen). There is significant ability to vary individual port flows and FiO2, but this must be done manually by adjusting the ball valves. It did not seem difficult and is readily accomplished using the liter meters.

Blending oxygen (100%) with room air was simulated using compressed air in the O2 line at 150 psi. This was regulated down to 3-4psi so that high oxygen line pressure would not prevent the room air check valve from opening. We did simulate that event to make sure it is an issue. It definitely is an issue, but one that is easy to detect with the liter meters. Once the oxygen is introduced to the line, if the pressure is too high, all of the liter meters will spike upward if combined flows are present. Flow in=flow out, so if the O2 flow as measured from the wall does not seem to be adding to the room air flow (in our case, flow on all ports initially dropped until we equalized the pressure), it’s because the O2 line pressure is holding the room air line check valve closed. Reduce the regulator pressure until the flows add. We noted an obvious increase at ~3-4 psi of O2 line pressure.

Thermal Testing (see photos and videos below)

During testing we kept a digital thermostat in the enclosure to evaluate the cooling fans’ ability to keep the electronics and pump cool. As long as the pump is moving forward air and the cooling fans are running, the box remained consistently at around 70 degrees F. When we switched to 100% O2 (using compressed air for testing), and stopped the pump, the temperature in the box rapidly spiked to 82 degrees F. At that point we opened the box and felt the surface of the pump, which was subjectively warm to hot. This is similar to turning off a car’s engine on a hot day. The coolant is not circulating through the engine at that point and the temperature rises significantly as a result. (Incidentally, this is why if your car is overheating you should pull over in a safe place (preferably in the shade); and stop the car but don’t turn off the engine. Let the engine idle to circulate coolant without the engine revving). The point being, if you turn off the pump to run 100% O2, open the lid of the enclosure to let heat vent out of the box. With the Rev2 units, the cooling fans are not running if the pump is not running.

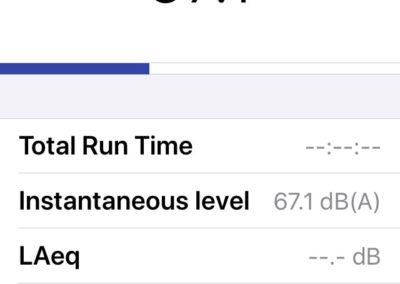

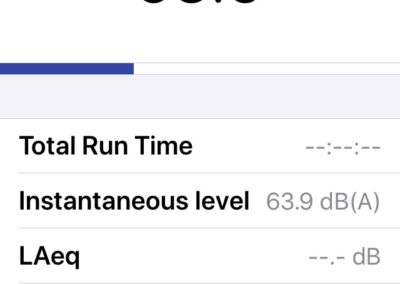

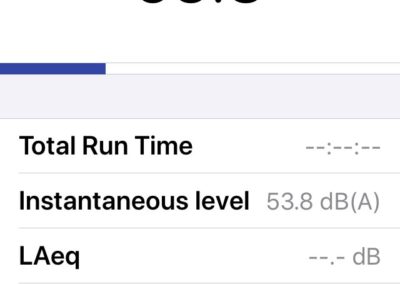

Testing Noise (see video below)

We also tested the Field Vent’s noise signature. Without sound insulation, the unit operates at around 75dB. With rubber padding mats and sound damping in the enclosure walls, it operates at a noise level of about 64-65dB. This seems to be reasonable for the amount of air output.

Note: To review the testing of the Rev 1 Unit, click here.

Testing videos

Videos about how we tested the components of the Rev 2 system.

First flow test of Rev 2 Unit

How to operate the HMI menus (and what the resulting flows look like)

Reducing fluctuations in flow using exhaust flow control

Noise testing shows around 65dB

Temperature and flow testing

Enclosure temperature monitoring

CPAP and two manual mode manifolds early in testing

CPAP, 2:2 BiPAP, and 1:1.6 I/E

CPAP, 2:2 BiPAP, and 1:1.6 I/E (Slow motion)

CPAP, 2:2 BiPAP, and 1:1.8 I/E

Legal Disclaimer

The content on this website is being released in this manner to maximize the potential public benefit during this urgent need for measures to respond to the COVID-19 crisis, including promoting potential ventilator manufacturing methods.

The content has not been reviewed or approved by the U.S. Food and Drug Administration (FDA). Interested readers are encouraged to contact the FDA and review available FDA materials, including their guidance on ventilators as well as the Department of Health and Human Services (DHHS) declaration of liability immunity for medical countermeasures against COVID-19.

PLEASE NOTE: The content has not been peer reviewed. The Authors make no representations or warranties of any kind (express or implied) relating to accuracy, safety, usefulness, usability, marketability, performance, or otherwise of the content released here. The Authors disclaim all express and implied warranties of merchantability and fitness of the content for a particular purpose, and disclaims all express and implied warranties regarding non-infringement of any patent, copyright, trademark, or other rights of third parties in the content or use of the content, or in the making, using, or selling products or services by any person or entity.

People or entities attempting to use the content in any way, including creating products or offering services, assume all risk and responsibility related to those uses, including all legal and regulatory compliance, safety, efficacy, performance, design, marketability, title, and quality. The Authors assume no liability related to the actions of third parties and in respect of any infringement of any patent, copyright, or other right of third parties.

The content has not been used in testing with humans at this time.

The Authors’ names and logos are trademarks or other exclusive property of the Authors. Readers of the content shall not use the name or logo of any Author in any way for publicity, advertising, or other commercial purposes, including linked to the reader’s products or services. Readers of the content shall not make statements or representations that, in Author’s sole judgment, deliberately or inadvertently claim, suggest, or give the appearance or impression of a relationship with or endorsement by that Author.

The Authors are proud of their affiliation with the University of Colorado as alumni and, in the case of Dr. Thomas Greany, as a professor at the Anschutz Medical Campus. The Authors express their appreciation to the University of Colorado for its support of this project.